Juri-Apollo Drews

No Cuts No Seams: Woven Alternatives to Cut-and-Sewn Garments

Juri-Apollo Drews, SACRe funded PhD project prepared at Ensadlab. Supervision: Aurélie Mosse, Claudia Mareis, Holly McQuillan.

No Cuts No Seams is a research-based textile and fashion design project which aims at producing entire zero-waste garments directly on a weaving loom that do not need to be cut or sewn after weaving.

In light of the current environmental crisis, profound changes are necessary in the construction of our garments. Today, the textile industry is producing woven fabrics in a rectangular format while neglecting the fact that very few garments worn in the Western world can be directly produced from this shape. Patterns are cut from these fabrics and subsequently assembled by sewing. This process generates considerable leftovers which make up 15 to 20% of the fabric initially produced.

Important progress has been made in the last years to produce seamless garments through knitting. Weaving, however, is still a rather unexplored technique in this domain. No Cuts No Seams proposes to look at the possibilities that updated and innovative weaving techniques could offer to replace the current cut-and-sew technique by questioning the rectangular shape of woven fabrics and by rethinking and restructuring the entire production chain. It sees itself at the crossroads of the disciplines of textile design, fashion design and textile engineering and aims for a much closer cooperation between these sectors.

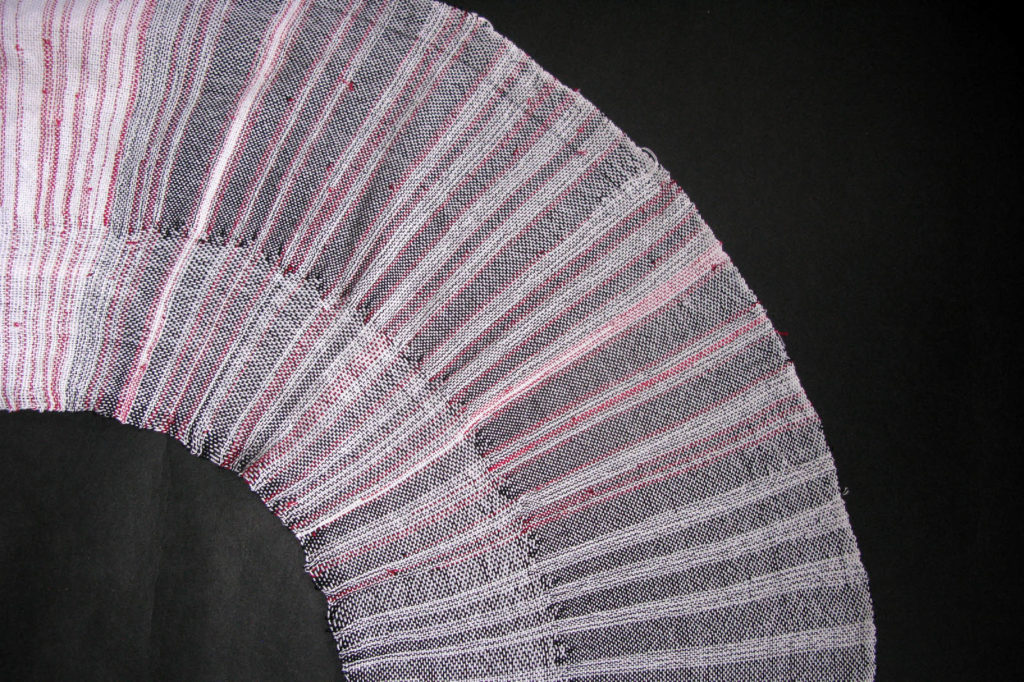

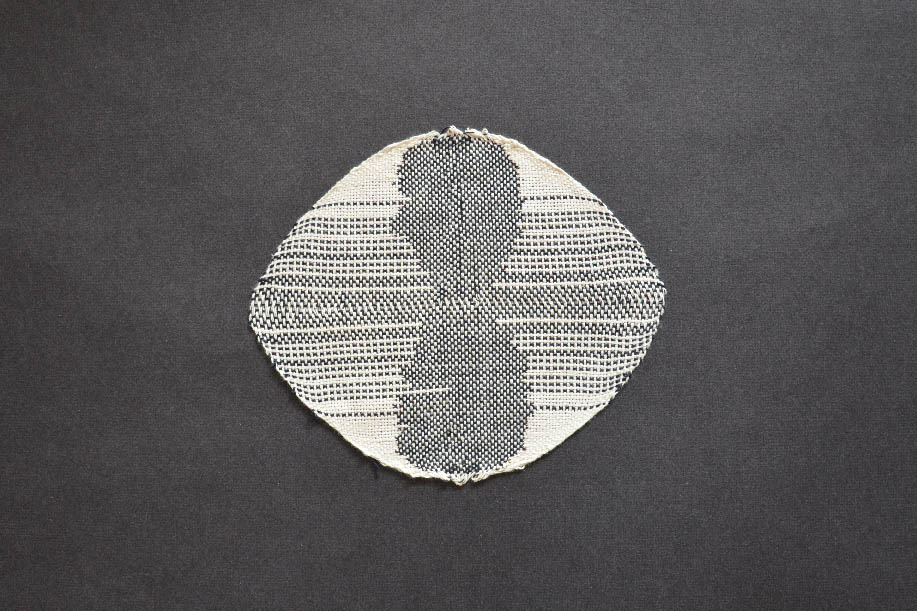

Since 2017, different innovative weaving techniques have been developed that change the orientation of the warp and weft fibres during the weaving process and that allow for a seamless connection between woven and knitted textile surfaces. Furthermore, studies have been made to produce more than two secured selveges to avoid the need for hemming. By altering an existing loom, a possibility to weave circular shapes instead of rectangular ones was created. The project so far comprises a number of samples and garments, most notably a prototype for a completely reversible seamless linen coat.

The current PhD project focuses on the development of further unconventional creative means to design and produce fully-fashioned and non-rectangular woven garments by redefining the role of the manual and mechanic loom as a tool and by proposing new looms or extensions to existing ones adapted to the production of such clothing. These new tools will offer alternatives to the current wasteful cut-and-sew method and could therefore contribute to a more sustainable reorganisation of the textile and clothing industries.

Related publications

- Drews, J.A., 2024, ‘L’enjeu des finitions dans le projet de tissage zéro-chute No Cuts No Seams, In: Castres, A., Cousin, C., et Duroselle, C. (eds), Rubans, galons, franges, coutures, lisières: Finitions textiles, Les Indes Savantes, AFET.

- Rosato, L., Drews, J.-A., Tour, A.; Bassereau, J.-F., Mosse, A., 2023, Seamlessness and Monomateriality in Sustainable Garment Design. A Knit/Woven Trouser Prototype, DIID, disegno industriale industrial design, n°80, pp.120-131.

- Drews, J., McQuillan, H.,and Mosse, A., 2023, Methods for Designing Woven Textile-forms: Examples from a pedagogical textile design workshop, In: Heinzel, T., Dumitrescu, D., Tomico, O., Robertson, S. (eds.), Proceedings of Textile Intersections Conference 2023, 20 – 23 September, London, United Kingdom. https://doi.org/10.21606/TI-2023/113.

- Drews, J.A., 2019, The Gap and How to Bridge It: attempts at reconciling weaving and garment making, master thesis, Paris: Ecole nationale Supérieure des Arts Décoratifs.